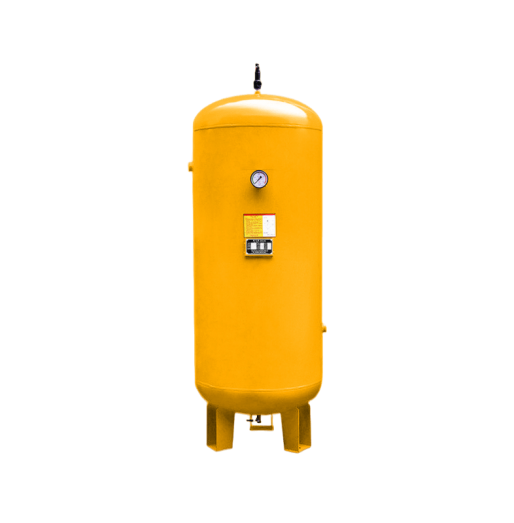

Skid-Mounted Air Compressor, 30HP-100HP, the compressor, refrigerated dryer, precision filters, and air receiver are all pre-piped and pre-wired on a single base. Once delivered, you only need to hook up power and the air line for it to run. After a complete Factory Acceptance Test (FAT) at the plant, on-site start-up and commissioning take just 2–4 hours before compressed air is ready.

Compact structure and space saving. Since the skid-mounted device adopts intensive layout and compact layout, it can greatly reduce the land occupation, which is of great significance for the oil and gas industry, which occupies a large amount of land.

Convenient demolition and easy to move. The skid-mounted device is easy to disassemble and assemble.

Indoor operation and cost saving. Most of the work is completed in the factory. On-site installation only requires installing the skid to the foundation, connecting the skid inlet and outlet pipelines, and wiring some electrical instruments, which greatly reduces the on-site workload and installation time.

View More >