Client’s information

One of the leading enterprises

A branch of a large Cement Group

A holding group company is a large-scale enterprise specializing in the production of high-grade cement. It is one of the twelve national large-scale cement enterprises supported by the Country and a leading enterprise in an industrial industry. As of January 2013, total assets were approximately 15.7 billion yuan, with approximately 10,000 employees, and more than 30 wholly-owned or holding subsidiaries, mainly located in Zhejiang, Jiangxi, Fujian, Sichuan, Yunnan, Guizhou, Guangxi, Hunan, Xinjiang and Gansu's 10 provinces and regions, New dry process production capacity of 60 million tons has been put into production, ranking 323rd among the top 500 Chinese manufacturing companies in 2012 and 60th among the top 100 companies in Zhejiang Province in 2012.

In our industrial production, the use of air compressors is indispensable everywhere. For the cement industry, the use of energy-saving air compressors is of great significance to relieve power supply pressure, improve the production environment, save cement production costs, and improve economic benefits. Since the Group establishment, it is sticking to the path of new industrialization, focused on development quality and efficiency, strengthened resource conservation and comprehensive utilization, and implemented energy conservation, emission reduction, and environmental protection.

Solutions

The cement industry is one of the important industries in various countries around the world and one of the largest energy consumers. Facing the contradiction between my country's energy consumption and economic and social development, saving operating costs has become a subject that must be studied.

In the cement production process, air compressors provide compressed air, which is mainly used for the transportation of powdery materials, dust removal, ash transportation, mixing, etc. Because these requirements for air consumption are relatively high, large screw air compressors are usually used.

AirHorse Permanent Magnet variable frequency screw air compressor BPM-50A

Energy saving effect analysis

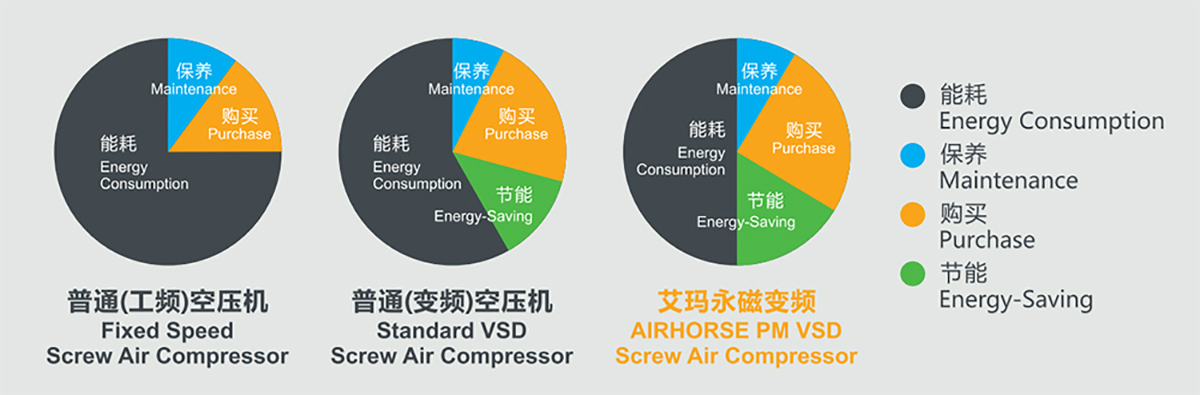

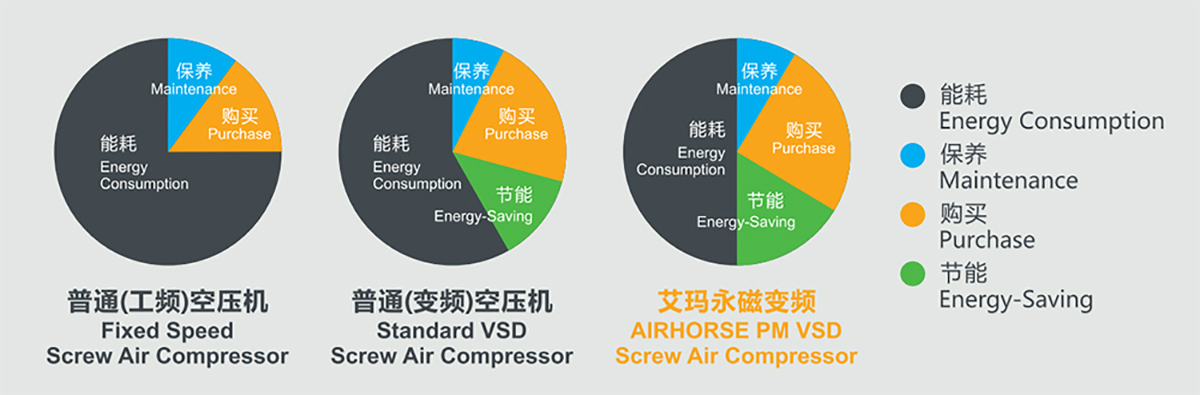

Comparative analysis of energy saving effects:

When purchasing an air compressor, the cost in the traditional sense (i.e. purchase cost + maintenance cost) only accounts for 25% of the total cost, while energy consumption accounts for 75%. Ordinary (variable frequency) air compressors save 10-20% more energy than ordinary (fixed speed) air compressors AirHorse permanent magnet variable frequency air compressor saves 33-35% energy than ordinary (fixed speed) air compressor

For example: 1. A 75KW ordinary air compressor operates 8,000 hours a year, and the electricity bill is 0.62 yuan/: kw.h. The annual electricity bill is: 75KW*8,000 hours*062/Kw.h=372,000 yuan

2. AirHorse permanent magnet frequency conversion 75KW Air compressor can save about 35% of energy in a year. Total energy: 372,000 yuan * 35% = 130,200 yuan

3. Investment return period (ROI): about 1 year