Guangzhou Airhorse compressor Co.ltd have many years of experience in compressor manufacturing and design. Now it has designed, developed and manufactured AHST Series single-screw water vapor compressors, with a maximum suction capacity of 3360 cubic meters per hour and a maximum steam supply temperature of 195℃. It is the steam compressor with the highest steam supply temperature in the world.

The original steam generation mode is that the heat pump and steam generator generates steam, which becomes low-temperature steam after use and is directly discharged. The application of Airhorse brand steam compressor is to inhale low-temperature steam through the compressor, and output finished steam after direct heating, it makes full use of the waste heat of low-temperature steam, saving energy, reducing carbon emissions and bringing great economic benefits to users.

The maximum air supply temperature is 195℃, which is the highest steam compressor supply temperature in the world,the hottest vapor compressor.

High temperature rise ,temperature rise 10-100℃

High temperature rise ,maximum air supply temperature 195℃

Advantages of single screw compressor technology:

Single screw compressor is a new type of positive displacement compressor developed in the past 20 years. It has the advantages of light weight, small size, simple structure, reliable operation, low vibration and noise, and simple maintenance,etc.

It has all the advantages of the traditional two-screw compressor, and has the characteristics of balanced force, small bearing load, no stress on the rotor meshing surface, and the star wheel rotor can be made of composite materials with excellent lubrication performance and wear resistance, thus improving the mechanical performance It is extremely reliable, the main bearing life can reach more than 100,000 hours (100,000h), and the noise and vibration are extremely ideal, both better than two-screw compressors.

AHST STEAM COMPRESSOR FEATURES :

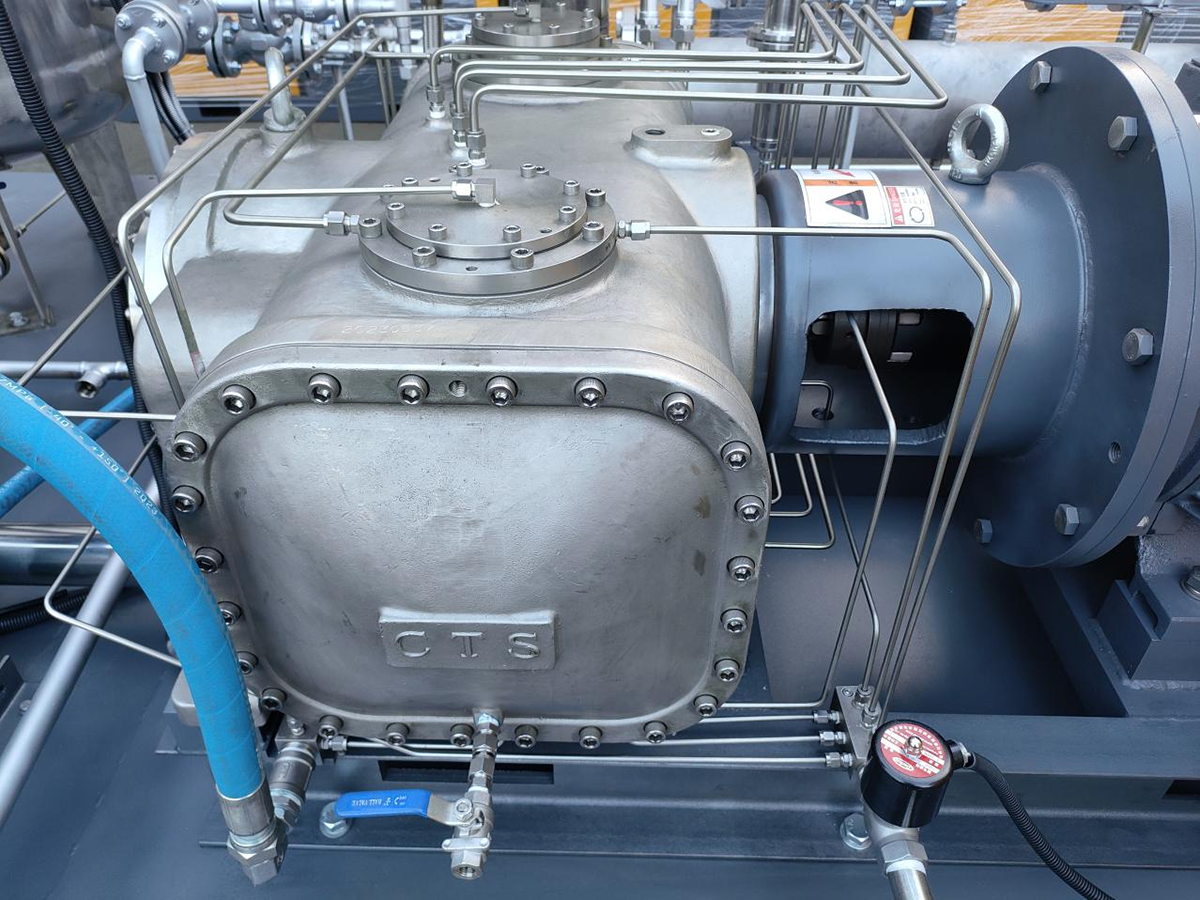

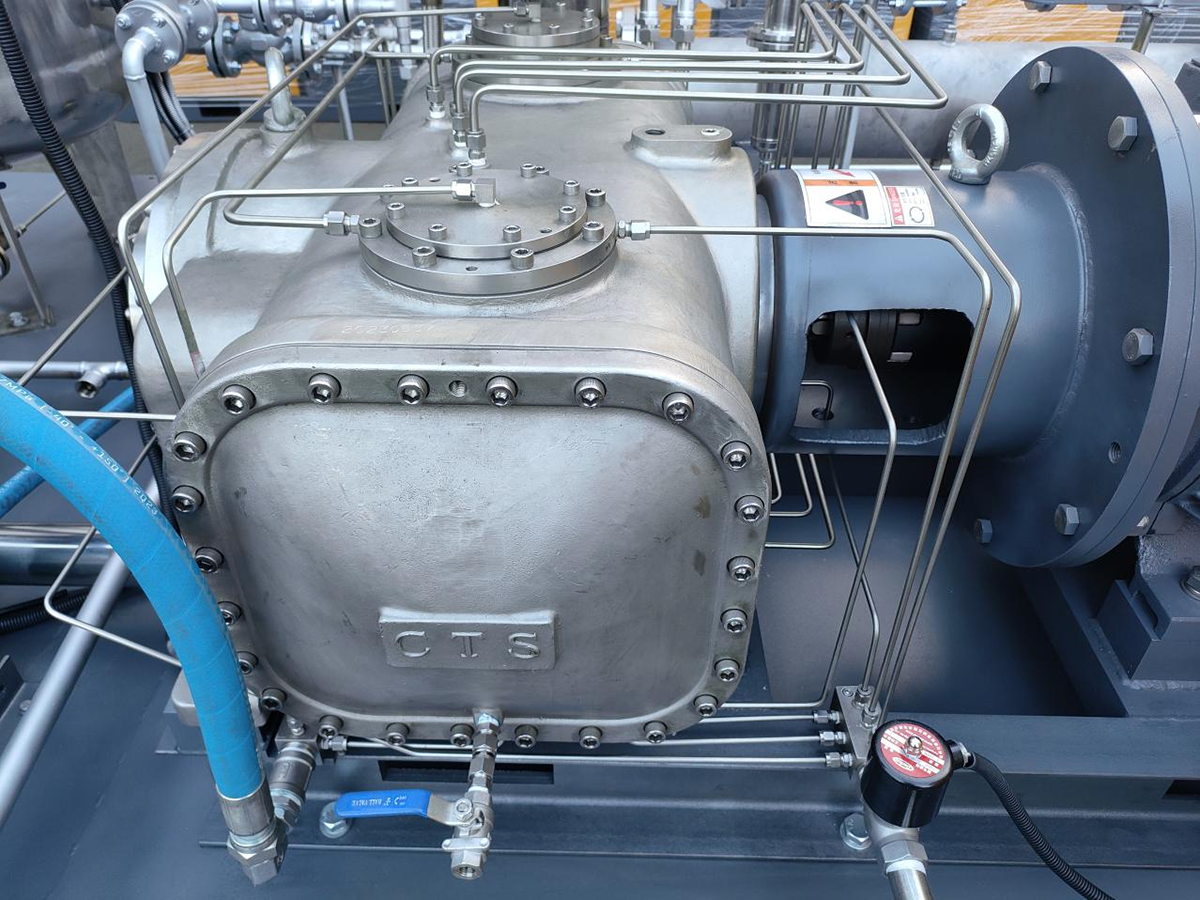

1. The Air end is made of stainless steel except the star wheel. Material selection includes 304,316L,2205 and 2Cr13

2. Have independent bearing lubrication system

3. Spray system

4. Single screw compression system

5. Gas will not leak

6. Absolutely oil-free

7. Airhorse steam compressor is specially designed for high temperature resistance, which can

After use, the waste steam is heated to reach the use temperature.

8. The operating inlet temperature is 70--165℃, and the maximum exhaust temperature can 195℃

Main functions of steam compressor:

1. Save energy consumption and recycle steam waste heat that cannot meet the temperature requirements;

2. Heat up the low-temperature steam to reach the required steam temperature;

Operating conditions: steam must be provided (heat pump and boiler are generated)

The heat pump heats up water. It heats up the hot water to the desired temperature, and then turns the hot water into steam through the steam generator. When the temperature of the generated steam does not meet the customer's needs, it will be discharged. It can also recycle the low-temperature steam, turn the steam into hot water, compress and heat it with the heat pump, and then turn it into steam through the steam generator.

Compared with the steam compressor, this process has a difference of more than 40% in energy consumption, which is more efficient and energy-saving than the steam compressor using low-temperature steam to heat up)

Airhose steam compressor has high cost performance:

At present, the steam on the market is basically 300-400 RMB/ton. Airhorse steam compressor can heat up the unused steam after use to reach the use temperature, and the cost can be controlled at about 200 RMB/ton. Every ton of steam energy can save more than 100 RMB;

If the displacement is 1 ton/hour, you can save 2400 RMB in one day.

One year (calculated by 300 days) can save 720,000RMB,

Steam compressor saves energy, allowing users to recover investment costs in a short time.